Top 5 Sealing Machines for 2023 Enhancing Efficiency and Reducing Costs in Packaging Industries

Table of Contents

- Top Innovations in Sealing Machines for Enhanced Packaging Efficiency

- Key Features to Look for in High-Performance Sealing Machines

- Cost-Benefit Analysis: Investing in Modern Sealing Technology

- How Automated Sealing Machines Transform Production Lines

- Tips for Choosing the Right Sealing Machine for Your Business Needs

- Future Trends in Sealing Machine Technology for the Packaging Industry

- FAQS

- Conclusion

- Related Posts

The packaging industry is always changing, and sealing machines are really playing a key role in making operations smoother and cutting costs. I recently came across a report by Smithers Pira that predicts the global market for packaging machinery will hit around $47 billion by 2025. A big part of this growth comes from new and improved sealing tech, which helps manufacturers fine-tune their production lines. As companies look for better ways to manage their supply chains, having reliable, efficient sealing machines has become more important than ever.

Dr. John Emerson from the Packaging Machinery Manufacturers Institute puts it nicely, saying, "Choosing the right sealing machine can seriously cut down on wasted materials and make sure packaging stays solid, which adds up to real savings in the long run." There are all sorts of sealing machines out there—heat sealers, vacuum sealers, you name it—and staying up-to-date on the latest innovations is crucial for businesses that want to stay competitive.

In this article, I’ll walk you through the top five sealing machines for 2023, showing how these cutting-edge tools are set to change the game when it comes to packaging efficiency in an ever-competitive market.

Top Innovations in Sealing Machines for Enhanced Packaging Efficiency

In 2023, the packaging industry is witnessing revolutionary innovations in sealing machines, aimed at enhancing operational efficiency and reducing costs. According to the Smithers Pira report, the global packaging market is expected to reach $500 billion by 2026, largely driven by advancements in technology and automation. These innovations in sealing machines play a crucial role, as they significantly streamline production processes and minimize downtime.

One of the standout developments includes the integration of IoT technology, which enables real-time monitoring and predictive maintenance of sealing machinery. This not only increases the longevity of the machines but also ensures consistency in packaging quality. A study by the Packaging Machinery Manufacturers Institute (PMMI) found that companies implementing smart sealing solutions can reduce their operational costs by up to 20%. Furthermore, advancements in materials such as heat-sealable films have improved the efficiency of sealing processes, resulting in a 30% reduction in material costs over traditional methods. These innovations are essential for businesses striving to optimize their packaging operations while remaining competitive in a rapidly evolving market.

Key Features to Look for in High-Performance Sealing Machines

In the rapidly evolving packaging industry, selecting the right sealing machine is crucial for ensuring operational efficiency while minimizing costs. The key features to look for in high-performance sealing machines include speed, energy efficiency, and versatility. According to a report by MarketsandMarkets, the global packaging equipment market is projected to grow from $40 billion in 2020 to $55 billion by 2025, indicating a significant push towards more automated and efficient solutions. High-speed sealing machines, capable of processing up to 200 packages per minute, can drastically reduce labor costs and increase throughput.

Another important feature is energy efficiency. An energy-efficient sealing machine can reduce operational costs by up to 30%, as highlighted in a study by the International Journal of Advanced Manufacturing Technology. Additionally, versatility in sealing applications is crucial, as businesses often deal with various materials and package types. Machines that can easily switch between tasks without extensive adjustments can save time and labor, further contributing to cost-effectiveness. In a highly competitive market, investing in machines that combine these features not only enhances productivity but also aligns with eco-friendly initiatives by reducing energy consumption and waste.

Cost-Benefit Analysis: Investing in Modern Sealing Technology

Investing in modern sealing technology is crucial for packaging industries aiming to enhance efficiency while reducing overall costs. Advanced sealing machines incorporate innovative features that streamline operations, minimize labor costs, and reduce material wastage. By automating the sealing process, companies can not only speed up production but also ensure consistent quality, which leads to reduced rework and less product spoilage. The initial investment in such machinery pays off quickly through increased throughput and savings on operational expenses.

Furthermore, modern sealing machines often come equipped with energy-efficient technologies that lower energy consumption and operational costs. Many of these machines also provide versatility to handle various packaging formats, reducing the need for multiple devices. This adaptability leads to lower capital expenditures and maintenance costs over time. When conducting a cost-benefit analysis, the long-term savings gained from enhanced efficiency, reduced labor, and lower material costs make investing in these innovative sealing solutions not just a strategic move, but a necessity for competitive packaging operations in 2023 and beyond.

How Automated Sealing Machines Transform Production Lines

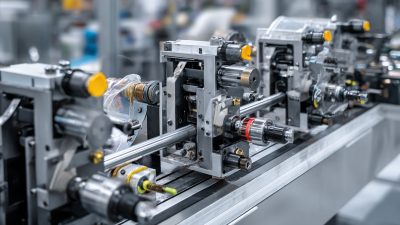

Automated sealing machines are revolutionizing production lines in the packaging industry, significantly enhancing efficiency and reducing operational costs. With the integration of technologies like robotic arms in manufacturing settings, companies can achieve higher throughput while maintaining consistent quality. This shift towards automation allows for faster packaging processes, ultimately leading to a more streamlined workflow.

For instance, recent upgrades seen in factories illustrate how fully automated production lines can handle high-capacity processing without compromising on performance. The seamless operation of these advanced machines not only boosts productivity but also minimizes labor costs, as fewer personnel are required to manage the processes. As packaging industries continue to embrace such innovations, the transformation in production lines signifies a pivotal moment in enhancing competitiveness and sustainability.

Tips for Choosing the Right Sealing Machine for Your Business Needs

When selecting the ideal sealing machine for your packaging business, it is essential to consider several key factors that align with your specific operational needs. According to a report by MarketsandMarkets, the global packaging machinery market is projected to reach $45.6 billion by 2025, which underscores the growing importance of efficiency in packaging processes. A vital aspect to evaluate is the adaptability of the machine to handle various materials, as versatility can significantly enhance production efficiency and reduce downtime associated with changeovers.

Another critical consideration is the machine's output capacity. For instance, if your production line demands high throughput, choosing a machine capable of sealing at high speeds can lead to substantial cost savings over time. The International Packaging Association notes that companies optimizing their packaging processes can achieve up to 30% reductions in operational costs. Additionally, look for features such as temperature control and sealing technology that ensure product integrity while minimizing waste, as these attributes can directly impact profitability by reducing material costs and errors during production.

Future Trends in Sealing Machine Technology for the Packaging Industry

The packaging industry is witnessing a significant transformation driven by advancements in sealing machine technology. According to a recent market analysis by Freedonia Group, the demand for automated sealing equipment is projected to grow by 4.5% annually, reflecting the industry's shift towards more efficient and cost-effective packaging solutions. As manufacturers seek to enhance productivity, innovations such as smart sealing machines equipped with IoT capabilities are on the rise, enabling real-time monitoring and predictive maintenance. This tech not only minimizes downtime but also optimizes operational costs.

Tips: When selecting a sealing machine, consider the integration of Industry 4.0 features, as this will likely position your operations ahead of competitors. Moreover, assess the scalability of the machine to adapt to future demands without significant additional investment.

Furthermore, sustainability trends are shaping the future of sealing technologies. The pursuit of eco-friendly packaging solutions is compelling manufacturers to innovate sealing processes that utilize biodegradable and recyclable materials. A recent survey by Packaging Strategies indicated that 75% of industry stakeholders are prioritizing sustainable practices to meet consumer expectations. Ensuring your sealing technology aligns with these trends not only enhances your brand image but also complies with evolving regulatory standards.

Tips: To stay ahead, focus on machines that offer versatility in material handling, as this flexibility will allow your packaging line to adapt to varying product requirements seamlessly.

FAQS

: Recent innovations include the integration of IoT technology for real-time monitoring and predictive maintenance, as well as advancements in materials like heat-sealable films, which streamline production processes and reduce material costs.

IoT technology enables real-time monitoring and predictive maintenance, increasing the longevity of the machines and ensuring consistency in packaging quality, resulting in operational cost reductions of up to 20%.

Key features to consider include speed, energy efficiency, and versatility, which collectively enhance operational efficiency and minimize costs in the packaging process.

Energy-efficient sealing machines can reduce operational costs by up to 30%, and they align with eco-friendly initiatives by decreasing energy consumption and waste.

High-speed sealing machines can process up to 200 packages per minute, drastically reducing labor costs and increasing throughput, making them vital for operational efficiency.

Automated sealing machines enhance efficiency and reduce costs through faster packaging processes, higher throughput, and maintaining quality, all while requiring fewer personnel to operate.

Versatility allows machines to easily switch between different tasks and materials without extensive adjustments, saving time and labor, and contributing to overall cost-effectiveness.

The global packaging equipment market is projected to grow significantly, indicating a trend towards more automated and efficient sealing solutions driven by technological advancements.

Innovations in sealing machines are crucial for businesses to optimize packaging operations, enhance productivity, and ensure competitiveness in a rapidly evolving market.

Conclusion

In 2023, the packaging industry is witnessing significant advancements in sealing machines, which are designed to enhance efficiency and reduce operational costs. Innovations in sealing technology are streamlining processes, allowing for faster production times and improved product integrity. Key features in high-performance sealing machines, such as automation, precision, and versatility, are critical for businesses looking to optimize their packaging operations.

Investing in modern sealing technology offers a strong cost-benefit analysis, with automated systems transforming production lines and workflows. As manufacturers like Guangdong Bochuan Machinery Technology Co., Ltd. continue to refine their sealing machines, businesses can expect to meet evolving market demands while maintaining high standards of quality. Choosing the right sealing machine tailored to specific business needs is essential, as emerging trends indicate a future focused on automation and smart technologies in the packaging industry.

Related Posts

-

How to Choose the Right Manual Sealing Machine for Your Business Needs

-

Discover the Secrets of Homemade Treats with a Candy Maker Machine

-

The Fascinating Journey of Candy Production Line from Concept to Confection

-

7 Essential Tips for Choosing the Perfect Candy Maker Machine

-

Ultimate Checklist for Choosing the Best DIY Candy Floss Machine: Expert Insights and Statistics

-

Ultimate Guide to Choosing the Best Lollipop Stick Machine for Your Production Needs