How to Choose the Right Manual Sealing Machine for Your Business Needs

Table of Contents

- Understanding the Different Types of Manual Sealing Machines available in the Market

- Key Features to Look for When Selecting a Manual Sealing Machine

- Assessing Your Business Needs: Volume, Product Type, and Sealing Requirements

- Comparing Costs: Budgeting for a Manual Sealing Machine Investment

- Tips for Maintenance and Care to Extend the Lifespan of Your Sealing Machine

- Real-Life Case Studies: Successful Implementations of Manual Sealing Machines in Businesses

- Revolutionizing Food Packaging: Insights from Industry Reports on the Efficiency of Jelly and Chocolate Automatic Filling and Sealing Machines

- FAQS

- Conclusion

- Related Posts

When it comes to food packaging, picking the right equipment can really make a difference in how smooth your business runs and how well your products stay fresh. One of those must-have tools is the Manual Sealing Machine. It’s super important for keeping your goodies looking good and tasting fresh—or at least, that’s what it’s there for! At Guangdong Bochuan Machinery Technology Co., Ltd., we’re all about designing, building, and selling a range of candy and food packing machines. We’ve been at it for a while, always trying to stay in tune with what our customers need and what the market’s asking for. In this post, I’ll walk you through some key things to think about when choosing a Manual Sealing Machine that’s just right for your specific needs. The goal? Help you make smarter choices so your packaging process becomes even better and more efficient.

Understanding the Different Types of Manual Sealing Machines available in the Market

When you're trying to pick out a manual sealing machine for your business, it’s pretty important to get a good handle on the different types out there. Basically, manual sealers come in mainly two flavors: impulse sealers and constant heat sealers. Impulse sealers are a hit because they can quickly and efficiently seal plastic bags or pouches. They work by giving a quick burst of heat — kind of like a momentary zap — which makes them perfect if you need to fast-pack small to medium batches.

On the flip side, constant heat sealers keep a steady temp, so they’re generally better for thicker materials or products that need a longer sealing process. You’ll often find companies in food packaging or pharma leaning on these because they’re reliable — you get airtight seals that help keep stuff fresh. Oh, and don’t forget to think about features like how wide the seal can be, whether the machine is portable, or how easy it is to operate. All those little things can really make a difference when you’re trying to keep up in a busy work environment.

How to Choose the Right Manual Sealing Machine for Your Business Needs

| Type of Manual Sealing Machine | Key Features | Best For | Price Range |

|---|---|---|---|

| Handheld Heat Sealer | Compact, easy to operate, ideal for small packages | Small businesses, home use | $20 - $50 |

| Foot Pedal Sealer | Hands-free operation, adjustable sealing time | Medium-sized businesses | $100 - $200 |

| Tabletop Manual Sealer | Durable, larger capacity, varied sealing widths | Restaurants, food packaging | $150 - $500 |

| Impulse Sealer | Quick sealing, no warm-up time, energy efficient | E-commerce, warehousing | $50 - $300 |

Key Features to Look for When Selecting a Manual Sealing Machine

When you're picking out a manual sealing machine for your business, it’s super important to get a good grip on the key features. Why? Because they can make or break how smoothly your packaging goes. For starters, one of the biggest deals is the temperature control. I came across a report from Packaging Strategies that said if the temperature isn’t just right, it can bump up product spoilage by about 30%—pretty shocking, right? So, having a machine that offers precise temperature calibration really helps keep your products fresh and high quality.

Another thing you wanna think about is how much the machine can seal at once and how fast it’s working. According to Freedonia Group, industries that use high-speed sealers can boost their productivity by up to 20%. So, it’s crucial to pick something that suits your production needs — not too slow, but reliable enough to keep up. Also, don’t forget about how easy it is to move around and operate. If you’re shifting the machine around your facility often, these factors matter. A user-friendly machine isn’t just about convenience; it can cut down training time and labor costs, which is a total win especially if your business is still growing.

Assessing Your Business Needs: Volume, Product Type, and Sealing Requirements

When you're picking out a manual sealing machine for your business, it's really important to start by figuring out what your actual needs are. Think about how much product you'll be sealing each day. If you're dealing with a lot—like, a big volume—that means you'll probably want a machine that's fast and efficient. But if you're only sealing a handful of items lightly, then a smaller, manual machine might do the trick. Understanding how much you plan to produce will really help you avoid overdoing it or spending too much on something you don’t actually need.

Next up, take a good look at what types of products you'll be sealing. Different materials—say, plastic, mylar, or aluminum—each need specific sealing methods to get a good seal without ruining the product. It’s also worth thinking about the size and shape of your packages. Having a machine that's flexible enough to handle different sizes and styles can come in handy as your product line grows or changes.

Lastly, don’t forget about the sealing technique itself—whether it’s heat sealing or cold sealing—as this can affect the quality and how long your products stay fresh. By keeping these things in mind, you'll be able to make a choice that really fits your business and helps you grow without any unnecessary headaches.

Comparing Costs: Budgeting for a Manual Sealing Machine Investment

When you're budgeting for a manual sealing machine, it's really important to look beyond just the sticker price. A lot of folks forget to factor in extra costs like maintenance, training, and packaging supplies — these can actually bump up your total expenses by 20 to 30 percent. For example, while a manual sealing machine might cost anywhere from $200 to $1,000, those hidden costs can add up quickly, affecting how you plan your finances and where you position your business.

**Quick tip:** Make sure to set aside some funds for unexpected repairs and regular upkeep. Trust me, it’s a lifesaver in avoiding sudden shutdowns. Also, don’t forget about training your staff. Investing a bit in proper training can make a huge difference in efficiency and can even help your machine last longer.

When it comes to choosing the right model, it’s worth looking at the long-term picture. Sometimes a pricier machine might seem costly at first, but it could seal faster and be more durable, which means lower operational costs over time. In fact, a study from Packaging Strategies showed that companies who went for higher-end models saw a 15% boost in production efficiency.

**Another tip:** Take your time and do some research. Check out different suppliers and models to find what fits your needs best. Remember, it’s not just about the initial price — consider the total cost of ownership to make a smart, well-informed decision.

Tips for Maintenance and Care to Extend the Lifespan of Your Sealing Machine

Taking good care of your manual sealing machine really matters if you want it to last and keep performing well, especially in any packaging biz. I read a recent report from Packaging Strategies that says doing regular maintenance can actually boost the lifespan of your sealing machine by up to 40%. That’s pretty huge considering how much you’ve probably invested — these machines are pretty much the backbone of your operations. So, to keep your machine in top shape, it’s a good idea to set up a routine that covers cleaning, lubrication, and checking out the parts.

One simple but important tip? Just wipe down the sealing surfaces with a soft cloth regularly to clear off any gunk or particles. Using a gentle detergent and avoiding anything abrasive can help prevent scratching or damage. Plus, don’t forget to lubricate the moving components as the manufacturer suggests — it helps reduce wear and keeps everything running smoothly. Also, it’s smart to check the temperature settings now and then to make sure they stay consistent, because even small fluctuations can mess with your seals.

And here’s another thing — make sure your operators are properly trained. When folks aren’t familiar with the right handling techniques, it can put unnecessary stress on the machine, shortening its life. Giving them some proper training can make a big difference, helping catch small issues before they turn into bigger problems. So, by following these simple tips, you’re not just keeping the machine happy — you’re also improving the quality of your products and saving money in the long run.

Manual Sealing Machine Performance Comparison

This bar chart compares the speed of different manual sealing machines measured in units per hour. Selecting the right machine based on performance metrics is crucial for meeting business needs and ensuring efficient operations.

Real-Life Case Studies: Successful Implementations of Manual Sealing Machines in Businesses

In today’s pretty competitive world, picking the right manual sealing machine can really make a difference in how smoothly things run. I’ve seen it myself — businesses that tweak their sealing methods to fit their specific needs often see a boost in both productivity and the quality of their products. Take a local bakery, for example. They started using a manual sealing machine to pack their baked goods, and honestly, it made things so much easier. Not only did it cut down on labor costs, but it also reduced waste, which means they could use their resources more smartly.

And here’s the thing — even as manufacturing moves more and more toward automation, manual sealing machines still hold their ground, especially for small-scale operations that want to keep a tight grip on accuracy and quality. I know a coffee distributor who upgraded to a manual machine because it gave them more flexibility and precision — perfect for handling all their different customer orders. Looking at these real-life stories, it’s pretty clear that investing in the right manual sealing equipment can really pay off, boosting productivity and making customers happier. Plus, it helps you stay in the game as the industry keeps heading toward robotics and full automation.

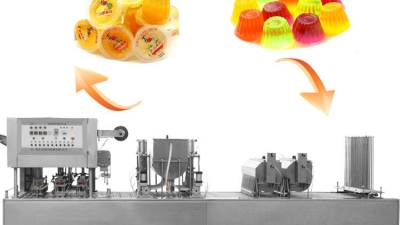

Revolutionizing Food Packaging: Insights from Industry Reports on the Efficiency of Jelly and Chocolate Automatic Filling and Sealing Machines

Revolutionizing Food Packaging: Insights from Industry Reports on the Efficiency of Jelly and Chocolate Automatic Filling and Sealing Machines

The food packaging industry is undergoing a significant transformation, with recent reports highlighting an increasing demand for automation in the packaging of products like jelly and chocolate. A notable study by Packaged Facts revealed that automated filling and sealing machines have improved production efficiency by an impressive 30% while significantly reducing labor costs. This surge in efficiency is crucial as manufacturers strive to meet the growing consumer demand for ready-to-eat products, which are projected to grow by over 25% in the next five years.

Introducing our latest innovation in food packaging technology – jelly cup filling and sealing equipment. This state-of-the-art machinery ensures the highest standards of hygiene and efficiency in the production process. Featuring advanced sensors and user-friendly interfaces, these machines are designed to not only enhance productivity but also maintain the integrity of the product. Reports indicate that businesses employing such technologies can reduce packaging waste by up to 20%, reflecting a commitment to sustainability alongside operational excellence.

Moreover, our jelly cup filling and sealing equipment is perfectly positioned to cater to the evolving landscape of food packaging. As consumers become more health-conscious and environmentally aware, the need for reliable and efficient packaging solutions has never been more paramount. Industry data suggests that companies adopting automated processes can deliver higher quality products, consistently meeting the expectations of today’s discerning consumers. This innovative machinery is the key to streamlining your production processes while delivering exceptional quality to your customers.

FAQS

: The main types of manual sealing machines are impulse sealers and constant heat sealers. Impulse sealers use a brief burst of heat for quick sealing, while constant heat sealers maintain a steady temperature for a consistent sealing process.

Impulse sealers are better for fast packaging solutions as they allow for quick and efficient sealing of materials.

Businesses should consider factors such as volume of products, types of materials to be sealed, package sizes, and specific sealing requirements, including heat vs. cold sealing.

For businesses handling a large number of items daily, a machine with higher efficiency and speed is necessary, while small-scale operations might manage with a compact, manual option.

Regular maintenance practices include cleaning the sealing surfaces, lubricating moving parts, checking temperature settings, and establishing a routine inspection schedule.

Operator training is essential as it helps ensure proper usage techniques, which can minimize stress on the machine and identify minor issues before they escalate.

A business might choose a constant heat sealer for its ability to create reliable, airtight seals, making it suitable for thicker materials or products like food and pharmaceuticals that need to preserve freshness.

It is recommended to clean sealing surfaces with a soft cloth and mild detergent, avoiding abrasive materials to prevent damage.

Regular maintenance can extend the lifespan of sealing machines by up to 40%, thus ensuring optimal performance and operational efficiency, which is crucial for packaging businesses.

Conclusion

Picking the right manual sealing machine for your business is a pretty important step if you want smooth packaging and to keep your products in top shape. The first thing you wanna do is get a good grasp of the different types out there because each kind is built to handle different production needs and product types. Some key features you should keep an eye on are sealing speed, how easy it is to operate, and how sturdy it is—that all plays a part in meeting your specific sealing needs.

Honestly, figuring out what your business really needs—stuff like volume, the kind of products you're sealing, and your budget—can help you pick the perfect machine. And don’t forget, investing in the right equipment isn’t just about now; it’s about the long term. Comparing prices can really help with planning your budget. Also, taking good care of your machine with regular maintenance is super important if you wanna make sure it lasts. Companies like Guangdong Bochuan Machinery Technology Co., Ltd. have some great success stories showing how choosing the right sealing tech can boost efficiency and stick to customer demands, especially in the food packing world.

Related Posts

-

Mastering Chocolate Bar Production: A Step-by-Step Guide to Optimizing Your Chocolate Bar Making Machine

-

Ultimate Checklist for Selecting the Perfect Candy Forming Machine: Key Industry Insights and Metrics

-

Discover Unmatched Quality with Chinas Best Foil Sealing Machines for Your Global Business

-

10 Amazing Candy Maker Machine Models You Should Try

-

Innovative Techniques for Optimizing Candy Manufacture Machine Efficiency

-

The Ultimate Guide to Maximizing Your Production with Soft Candy Making Machines